The Booming Industry of China CNC Parts Supply

China CNC parts supply has become a significant focus for manufacturers across the globe, primarily due to the nation's reputation for producing high-quality, precision-engineered components at competitive prices. This article delves into the various facets of CNC parts manufacturing in China, exploring its immense potential for businesses aiming to enhance their efficiency and profitability in the metal fabrication industry.

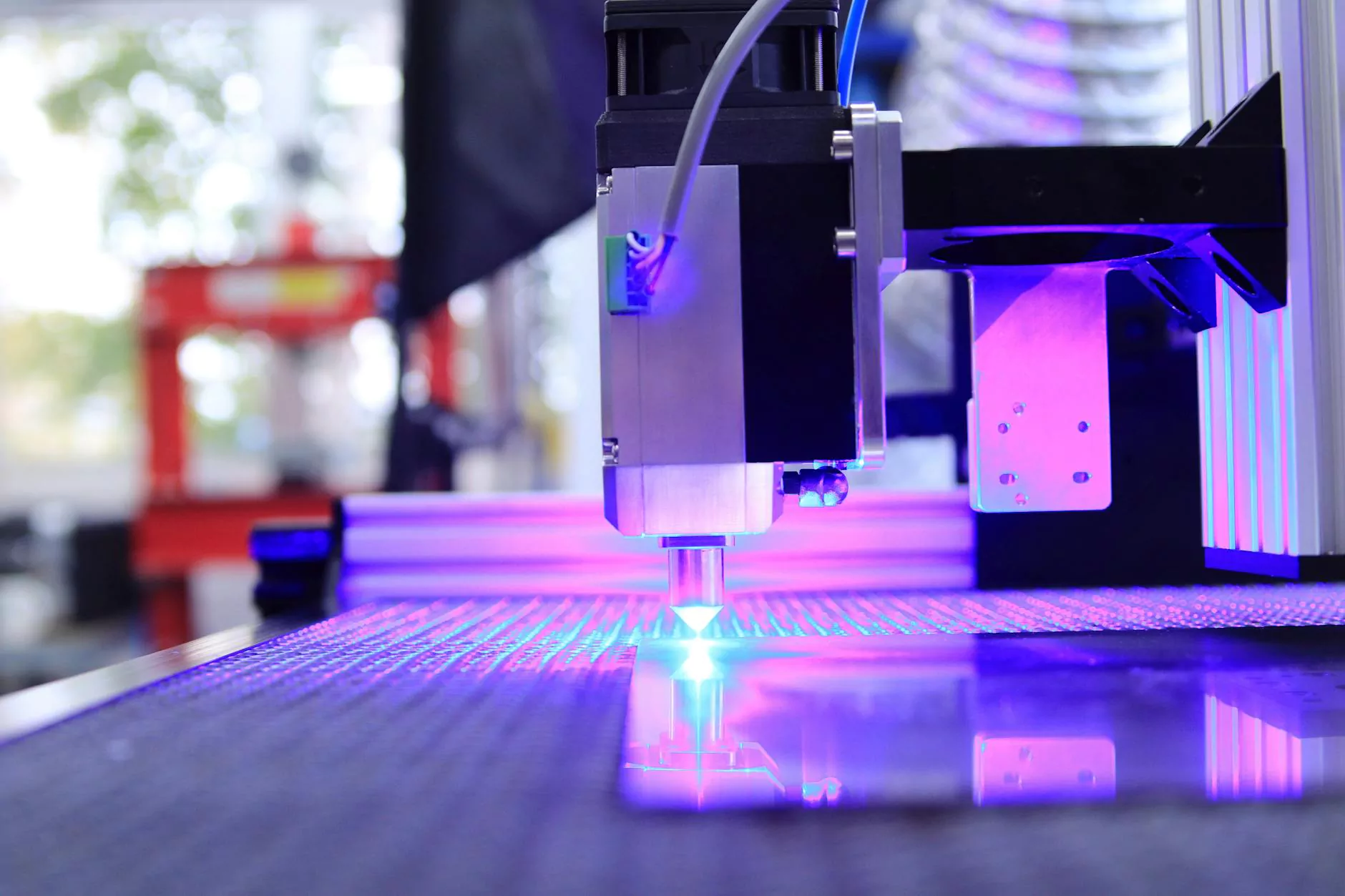

Understanding CNC Technology

CNC, or Computer Numerical Control, refers to the automation of machine tools through the use of computers executing pre-programmed sequences of machine control commands. CNC machines are essential for modern manufacturing processes, enabling precision machining of complex parts with minimal human intervention. Here’s why CNC technology is indispensable:

- Precision: CNC machines can reproduce complex geometries with incredible accuracy.

- Efficiency: Automated processes lead to faster production times.

- Versatility: CNC machining can work with various materials, including metals, plastics, and composites.

- Consistency: CNC equipment produces identical parts, crucial for large-scale manufacturing.

The Importance of Supplier Selection

When it comes to manufacturing, the selection of suppliers is critical. The China CNC parts supply chain is renowned for offering myriad options, but businesses must navigate this landscape wisely. Here are some key considerations to keep in mind:

1. Quality Assurance

It’s essential to partner with suppliers that maintain rigorous quality control standards. Look for manufacturers that have certifications such as ISO 9001, which guarantees consistency and quality in production processes.

2. Cost Efficiency

One of the primary reasons businesses turn to China for CNC parts is the competitive pricing. Yet, companies must ensure they’re not sacrificing quality for cost. Evaluating overall value—including shipping, lead times, and reliability—is crucial.

3. Communication and Support

Effective communication can significantly affect the success of international partnerships. Establish whether the supplier has English-speaking representatives and what kind of support they offer post-sale.

Benefits of Sourcing CNC Parts from China

Outsourcing components from China CNC parts supply provides many advantages that can greatly benefit manufacturers. Here are some of the most compelling reasons:

1. Reduced Production Costs

China’s well-established infrastructure and labor market allow manufacturers to offer lower prices than many other countries. This cost-effectiveness is advantageous for businesses looking to scale while maintaining a healthy profit margin.

2. Access to Advanced Technology

Chinese manufacturers continually invest in cutting-edge technology. This means that companies sourcing parts from China can take advantage of the most sophisticated CNC machines and production techniques.

3. Scalability

Manufacturers can easily scale their operations without facing constraints. Chinese suppliers often have the capacity to handle large orders, enabling businesses to expand their production as needed.

Navigating the Challenges of China CNC Parts Supply

While the benefits are clear, there are challenges that come with sourcing from abroad. Addressing these proactively can lead to smoother operations:

1. Language Barriers

Understanding technical specifications and managing orders when there are language differences can complicate transactions. Companies should consider enlisting the help of translators or bilingual staff when necessary.

2. Quality Concerns

While many Chinese manufacturers are reputable, others do not meet international standards. Conducting thorough due diligence and possibly visiting facilities can mitigate these risks.

3. Intellectual Property Risks

Companies must ensure that their designs and technical specifications are protected. Signing non-disclosure agreements (NDAs) and ensuring compliance with local laws is essential in this regard.

Strategies for Successful Partnerships

To maximize the benefits of China CNC parts supply, companies should adopt certain strategies when partnering with suppliers:

1. Build Long-Term Relationships

Establishing long-term relationships with reliable suppliers can foster trust and open channels for better negotiations, improved quality, and more favorable terms.

2. Invest in Research and Development

Collaborate with suppliers on R&D to create tailored solutions that meet specific business needs. Innovation can lead to competitive advantages in the market.

3. Monitor Supply Chain Performance

Implement continuous improvement strategies to monitor and optimize the supply chain. This may involve regular audits and feedback loops with suppliers to ensure alignment with your business goals.

Future Trends in CNC Parts Supply from China

The landscape of China CNC parts supply is constantly evolving, driven by technological advances and market demands. Here are some emerging trends:

1. Increased Automation

As more manufacturers adopt automation, the demand for CNC parts will continue to grow. Chinese suppliers are poised to benefit from this trend by meeting the rising needs for advanced, automated solutions.

2. Sustainable Manufacturing Practices

Environmental concerns are prompting manufacturers to seek out suppliers who prioritize sustainability. Chinese manufacturers are beginning to adopt more eco-friendly practices in their production processes.

3. Digital Transformation

With the rise of Industry 4.0, manufacturers are increasingly relying on data analytics and IoT to enhance productivity. This shift will influence how CNC parts are manufactured and supplied, paving the way for smarter supply chains.

Conclusion: The Bright Future of CNC Parts Sourcing

In conclusion, the significance of China CNC parts supply in the global manufacturing landscape cannot be overstated. By carefully selecting suppliers, understanding the intricacies of CNC technology, and staying ahead of market trends, businesses can greatly enhance their operational efficiency and profitability. As the manufacturing industry continues to evolve, those who adapt and leverage the expertise of China's CNC capabilities will undoubtedly thrive in the competitive arena of metal fabrication. By embracing these strategies, manufacturers can secure a stable and cost-effective supply of high-quality CNC parts that will propel their businesses forward.